http://crowncapitalmanagement.bravesites.com/entries/business/crown-capital-eco-management-political-industry-leaders-aim-to-bolster-steel-s-status-in-u-s-The weather forecast in Washington these days is cloudy with a chance of gridlock, based on interviews with steel industry representatives. In the next few years, political and business leaders say trade groups will play an increasingly important role advocating on behalf of the steel industry. They say it also will be important to push current and future White House administrations to develop policies supporting the manufacturing sector, which likely will include discussions on how to handle international trade relations. Lack of consensusInternational trade has been one of the strongest lobbying platforms the domestic steel industry has promulgated as the share of imports consumed has grown in the last few decades. In the last few legislative sessions, U.S. Rep. Pete Visclosky, D-Merrillville, said there hasn't been a majority of members in the House or Senate who have been willing to take "forceful, compelling action on trade." Visclosky has backed legislation to add countervailing duties on imports from countries that have an undervalued currency. The House passed the measure in 2010, but it died in the Senate. The following year, the Senate approved a similar measure, but it wasn't brought to the House floor for a vote. "That's not getting the job done," Visclosky said. "And that's (just) one example." In the future, Visclosky said it will be important for the government to respond faster with trade remedies. Typically, petitions are filed seeking trade relief after the industry has suffered significant damage and jobs are lost. He said if the system were improved to compress the time frame for trade cases and so customs personnel could spot duty violations, the domestic industry would benefit greatly. "Steel, while it's profitable today, remains under great competitive pressures," Visclosky said. Thomas Gibson, American Iron and Steel Institute CEO, said the industry has received good support from the Department of Commerce and individuals working in trade relations with the government. However, he said would like to see more support from the Oval Office.

http://crowncapitalmng.livejournal.com/Princeton film festival explores broad range of environmental issues Sometimes the best way to educate is to entertain; this has proven true by Princeton Public Library for the seventh straight year. Last weekend was the start of the annual Princeton Environmental Film Festival, the festival features more than 30 films that explore environmental sustainability from a wide range of perspectives. The film series will run from now through Feb. 10, with 13 days of free films for 2013. “An Inconvenient Truth” and “Who Killed the Electric Car?” pave the way to the annual festival. Curator Susan Conlon says the library was inspired to create the film festival after the overwhelming success of two environmentally themed films. “The festival is a way to bring these kinds of films to the community; to explore new ideas and become aware of different perspectives,” Conlon says. “There are often more than two sides to an issue, and these films really make you expand your thinking.” It isn’t just the quantity of the film yet the quality as well, Conlon stresses that while the majority of the films address environmental matters, every film was primarily selected not just because it addressed a specific issue, but because it was a well-made, entertaining film. As diverse as the films may be, Conlon notes that they are all linked by a common theme. This year’s films explore a wide range of topics and present perspectives from literally around the world.

http://crown-capital-eco.blogspot.co.uk/2013/01/crown-capital-eco-management-biomass.htmlCrown Capital Eco Management Indonesia – The heavily forested city of Ketchikan, Alaska, is built on rock and surrounded by water. Every commodity that comes into Ketchikan must arrive by sea or air. The use of fuel oil is problematic for both economic and environmental reasons because the oil must be obtained and refined elsewhere and transported (using additional fuel). What’s more, fuel oil is subject to price instability.Southeast Alaska Discovery Center in Ketchikan, which provides information to more than a million visitors each year, is the site of a pilot biomass boiler system now coming to life. Two oil-fired boilers serving the 250,000-sq-ft center were replaced with a highly efficient system fueled by local wood. Manufactured by Hurst Boiler & Welding Company Inc., the hot-water boiler was custom-designed to fit within very limited indoor space.Under the direction of E. Dane Ash, project manager for Tyonek-Alcan Pacific LLC, the biomass boiler system was developed with Hurst representative Gregory W. Smith of Global Energy Solutions Inc. to address environmental concerns, as well as issues related to building space, fuel costs, comfort, reliability, and simplicity of operation.The new boiler is located on the lower level of the Discovery Center, which requires heating for a minimum of nine months a year. Local wood densified into fuel pucks is delivered to an elevated walking-floor storage bin in a vestibule area built to protect against excessive moisture. (The biomass-fired boiler can burn any wood product with up to 50-percent moisture content.) An auger moves pucks from the storage area to a metering bin and into the boiler. Freezing is not an issue because the walking floor easily breaks up any frozen contents.The boiler system was designed to highlight how biomass can reduce or eliminate the use of fossil fuels. Visitors can see the boiler operate through specially designed windows. In the hall just outside of the boiler room, the noise level and ambient temperature is consistent with the rest of the building.SavingsFuel costs have been cut by two-thirds. The densified pucks are used with almost no residual ash; eventually, however, tree clippings from the Ketchikan walking trails will be ground and fed into the boiler, eliminating the need for transport to a landfill, burning, and other methods of disposal.The BoilerThe Hurst S100 Series Fire Tube 27 HP Hydronic Water Heating Boiler features a pre-heater to optimize combustion and an underfeed stoker with dry-ash-removal system.ResultsThe system easily can be replicated for heat or heat/power generation up to 20,000 kw. In June 2011, Smith served as a keynote speaker for the fifth annual Native American Economic Development Conference in Anaheim, Calif., where he described the initiatives being implemented in Ketchikan and shared success stories of biomass-fired boiler systems installed on institutional campuses and in manufacturing facilities throughout the United States, particularly in challenging and remote locations. Systems include municipal solid waste, as well as woody biomass for steam production and steam to power.

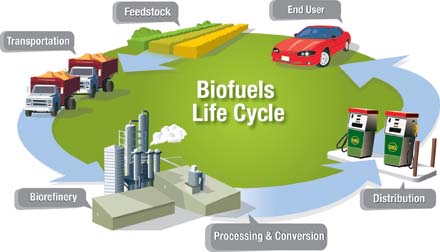

http://equiefahp.inube.com/blog/2521484/crown-capital-eco-management-biomass-as-a-fuel-for-boilers/Biomass for energy often mean plant base material although can equally apply to both animal and vegetable draw from material. Biomass is actually a biological material derive form living or recently living organisms. Biomass chemical composition is carbon based and is composed of a mixture of organic molecules containing hydrogen, usually including atoms of oxygen, often nitrogen and also small quantities of other atoms, including alkali, alkaline earth and heavy metals, metals are often found in functional molecules such as the porphyrins which include chlorophyll which contains magnesium. There are five basic categories of material of biomass such as: •Virgin wood- from forestry, arboriculture activities or from wood processing. •Energy crops- high yield crops grown specifically for energy applications •Agricultural residues- residues from agriculture harvesting or processing • Food waste- from food and drink manufacture, preparation and processing, and post-consumer waste •Industrial waste and co-products- from manufacturing and industrial processes. The question is how are we going to use this biomass as a fuel for boilers? But what is a boiler in the first place? A boiler is defined as “a closed vessel in which water or other liquid is heated, steam or vapor is generated, steam is superheated, or any combination thereof, under pressure or vacuum, for use external to itself, by the direct application of energy from the combustion of fuels, from electricity or nuclear energy.”

NIFES Consulting Group commissioned by Calor Gas showed that commercial buildings can reduce carbon emissions by 22 per cent by replacing an old oil boiler with one that uses LPG. This was partly a result of a more efficient system, and partly a result of the emissions factor for fuel oil standing at 0.265 kilograms of CO2 per kWh, higher than that of LPG, which comes in at 0.214 kilograms of CO2 per kWh. In addition, a separate study published earlier this year in the peer-reviewed journal Environmental Impact Assessment Review earlier proved that, in domestic buildings, heating oil generates about 20 per cent more greenhouse gas emissions than LPG. It is also more energy efficient. The same NIFES study also showed that an oil boiler installed 15 years ago replaced with LPG can cut energy use by 11 per cent. http://crowncapitalecomanagement.spotlife.se/

|

RSS Feed

RSS Feed